Understanding Oxygen Generation Plants

What is an Oxygen Generation Plant?

An Oxygen Generation Plant is a system that produces high-purity medical oxygen using Pressure Swing Adsorption (PSA) technology. This process extracts oxygen from the surrounding air and delivers it at the required purity levels for medical use. Oxygen generator plants are widely used in hospitals, clinics, and emergency medical facilities to maintain a consistent and reliable oxygen supply.

How PSA Oxygen Generator Works

The PSA (Pressure Swing Adsorption) process is a proven method for generating high-purity oxygen directly from ambient air. This method involves four key steps:

- Air Compression and Drying

- Atmospheric air (which contains 20.9% oxygen, 78% nitrogen, 0.9% argon, and trace gases) is compressed and passed through a refrigeration dryer to remove moisture.

- Filtration and Purification

- The compressed air is purified using a multistage filtration system that removes contaminants, ensuring clean air enters the oxygen generator.

- Oxygen Separation Using PSA Technology

- The purified air is passed through zeolite molecular sieves that selectively adsorb nitrogen, allowing oxygen to pass through. This results in oxygen purity levels of 93% (±3%), with higher purity available on demand.

- Oxygen Storage and Distribution

- The generated oxygen is stored in oxygen storage tanks and distributed through hospital pipelines or filled into medical cylinders for later use.

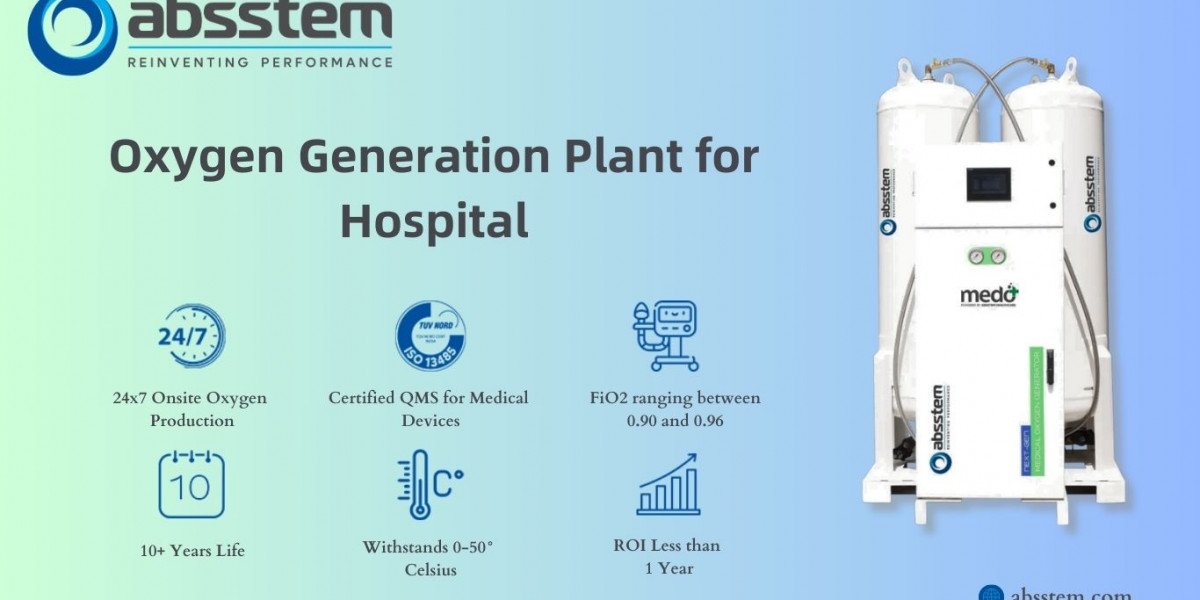

Key Features of Oxygen Generation Plants

Modern oxygen generation systems ensure maximum efficiency, reliability, and ease of use. Here are some standout features:

- Certified QMS for Medical Devices: The plant complies with ISO 13485 certification, ensuring quality and safety.

- FiO2 Ranging Between 90-96%: Provides high-purity oxygen suitable for medical applications.

- 24x7 On-Site Oxygen Production: Eliminates reliance on external suppliers.

- Global Manufacturing Standards: Meets international compliance for medical oxygen generation.

- Advanced Display & Control System: Includes a touchscreen monitor and oxygen purity analyzer for real-time monitoring.

- Compact and Ergonomic Design: Saves space and allows easy installation.

- Long Life and Low Maintenance: Designed to last over 10 years with minimal maintenance requirements.

- Withstands Extreme Temperatures: Operates effectively between 0-50°C.

Benefits of Installing an Oxygen Generation Plant in Hospitals

1. Consistent and Reliable Oxygen Supply

Oxygen is essential in ICUs, operation theaters, and emergency wards. Having an in-house oxygen generation system ensures continuous and uninterrupted oxygen availability without the risks associated with cylinder shortages or supply chain disruptions.

2. Cost-Effective Solution

Compared to purchasing liquid oxygen or cylinders, on-site oxygen generation significantly reduces costs. Hospitals recover their investment within a year due to the savings on refilling and transportation costs.

3. Fully Automated and User-Friendly Operation

Modern oxygen plants come with an advanced display and control system, making them easy to operate with minimal manual intervention. Live system monitoring ensures smooth functioning.

4. Easy Installation and Maintenance

Oxygen generators are designed with a Plug & Play mechanism, making installation quick and simple. The lowest maintenance cost ensures hospitals do not face unexpected expenses.

5. Enhanced Patient Care

Having a consistent oxygen supply means better patient outcomes, particularly in critical care situations, emergency surgeries, and respiratory therapies.

6. Environmental Benefits

By eliminating the need for frequent transportation of oxygen cylinders, hospitals reduce their carbon footprint, making in-house oxygen generation an eco-friendly solution.

Engineering & Technical Specifications

Oxygen generation plants are built with high-quality engineering components to ensure reliability and longevity. Here are the integral components of an oxygen generator system:

- Refrigeration Dryer – Removes moisture from compressed air.

- Air Tank – Minimizes pulsation and ensures steady airflow.

- Multistage Filtration System – Removes contaminants for pure oxygen production.

- Inlet Air Monitoring System – Prevents contamination of molecular sieves.

- PSA System – Generates oxygen using zeolite molecular sieves.

- Storage System – Stores oxygen for immediate use.

- HEPA Filter – Ensures bacterial contamination is removed before oxygen reaches the patient.

Technical Data:

- Inlet Air Quality: ISO 8573.1:2010 - Class 1.4.1

- Medical-Grade Compliance: US, EU, UK, and Indian Pharmacopeia

- Sound Level: 65 dB from 1-meter distance

- Oxygen Flow Rate: 2.5 to 250 Nm³/hr

- Oxygen Delivery Pressure: 5.3 barg

- Oxygen Purity: 93% (±3%)

- Operating Temperature: -5°C to 45°C

- Power Supply: 230 VAC, 50/60 Hz

- Certification: ISO 13485, ISO 9001:2015, CE Certified

Frequently Asked Questions (FAQs)

1. What is the lifespan of an oxygen generation plant?

- Most oxygen plants have a lifespan of over 10 years with proper maintenance.

2. How much does it cost to install an oxygen generation plant in a hospital?

- The cost varies based on capacity and specifications, but the investment is usually recovered within one year due to cost savings.

3. Is the oxygen produced safe for medical use?

- Yes, oxygen meets international medical standards and is compliant with US, EU, UK, and Indian Pharmacopeia.

4. Can the plant operate in extreme temperatures?

- Yes, the system is designed to function effectively between -5°C to 45°C.

5. How does an oxygen generation plant benefit hospitals?

- It ensures a continuous supply of oxygen, reduces costs, enhances patient care, and makes hospitals independent of external suppliers.