The welding consumables market is integral to several industries, including automotive, construction, aerospace, and manufacturing. These consumables are essential for welding operations, providing the necessary materials such as electrodes, filler metals, and flux. As the demand for welding consumables grows with industrial advancements and increasing infrastructure projects, market research has become pivotal in understanding the trends, challenges, and future outlook of this sector. This article delves into key findings and insights from welding consumables market research, focusing on trends, growth drivers, technological innovations, competitive dynamics, and regional influences shaping the market.

Growth Drivers in the Welding Consumables Market

The welding consumables market has witnessed significant growth due to the expansion of industries such as construction, automotive, and energy. The demand for high-quality welding consumables has increased with the rise of industrialization and urbanization. Market research indicates that the growing construction and infrastructure development in emerging economies is a major driver for the increased consumption of welding consumables. Additionally, the automotive industry's shift toward lightweight materials and advanced manufacturing processes has fueled the need for specialized welding consumables. The continuous development of new welding technologies, such as robotic welding and automated systems, further boosts demand as industries seek efficient and precise welding solutions.

Technological Innovations Impacting the Market

Technological innovation plays a crucial role in the welding consumables market. Research highlights the development of advanced welding processes, such as laser welding, friction stir welding, and additive manufacturing (3D printing), which are reshaping the consumables landscape. These cutting-edge techniques require specialized consumables designed to withstand higher temperatures and stress levels. Moreover, the introduction of more durable and versatile consumables has improved welding performance, leading to increased adoption across industries. Market research also points to a rise in hybrid welding technologies, where consumables are tailored to support various welding methods. Companies are increasingly investing in research and development to create products that cater to these new technologies, thereby driving market growth.

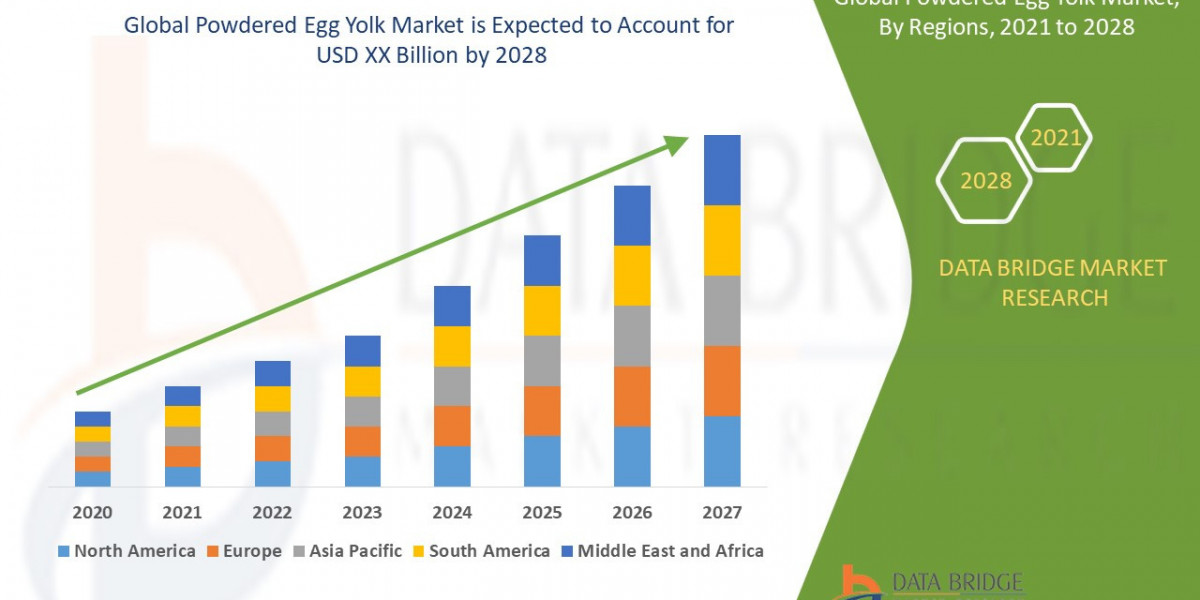

Regional Market Trends

Regional variations in the welding consumables market are influenced by factors such as industrial growth, government regulations, and infrastructure development. North America and Europe remain strong markets due to their established manufacturing bases and advanced industrial sectors. However, the Asia Pacific region, particularly China and India, is seeing rapid growth driven by large-scale industrialization, urbanization, and a booming construction industry. Research indicates that developing nations in the Middle East and Latin America are also becoming important consumers of welding consumables as they invest heavily in infrastructure projects, energy production, and manufacturing capabilities. Understanding regional dynamics is essential for businesses aiming to expand their footprint in these emerging markets.

Competitive Landscape and Key Players

The welding consumables market is highly competitive, with numerous global and regional players offering a wide range of products. Key market players include multinational corporations such as Lincoln Electric, ESAB, Air Liquide, and Panasonic. These companies invest heavily in research and development to enhance the performance of their products and maintain a competitive edge. Market research reveals that product innovation, strategic mergers, and acquisitions are some of the strategies employed by leading players to strengthen their market position. Additionally, companies are focusing on expanding their distribution networks to reach untapped regions and meet the growing demand for welding consumables in emerging economies.

Environmental Regulations and Sustainability Efforts

Increasing environmental concerns and stringent government regulations are influencing the welding consumables market. Research highlights the shift toward eco-friendly consumables that comply with environmental standards, reducing harmful emissions during welding processes. Manufacturers are working to produce consumables that minimize waste and are made from sustainable materials. This growing emphasis on sustainability is pushing the market towards greener alternatives, driving the development of low-emission welding consumables and efficient production methods. Furthermore, research into reducing the carbon footprint of manufacturing processes is gaining traction, especially with the growing focus on corporate social responsibility.

Challenges in the Welding Consumables Market

Despite the market’s growth, several challenges hinder its progress. The volatility of raw material prices, such as steel and aluminum, presents a significant threat to manufacturers, leading to fluctuations in the cost of consumables. Market research highlights that this volatility can affect product pricing and create uncertainties in the supply chain. Additionally, there is a shortage of skilled labor in the welding industry, especially in advanced welding techniques. The lack of qualified welders in certain regions could limit the demand for welding consumables. Overcoming these challenges will require manufacturers to adopt cost-effective production strategies, invest in workforce training, and maintain flexibility in their supply chains.

Future Market Outlook

The future of the welding consumables market looks promising, with steady growth anticipated across various regions. As industries continue to adopt advanced welding technologies and sustainable practices, the demand for specialized consumables will increase. Research indicates that new welding techniques, such as hybrid welding and additive manufacturing, will further fuel market growth by creating new opportunities for consumable innovation. Additionally, increasing investments in infrastructure development and manufacturing projects in emerging economies will contribute to the market’s expansion. Companies that can navigate the challenges of price volatility, labor shortages, and regulatory requirements will have a competitive advantage in the evolving market landscape.