views

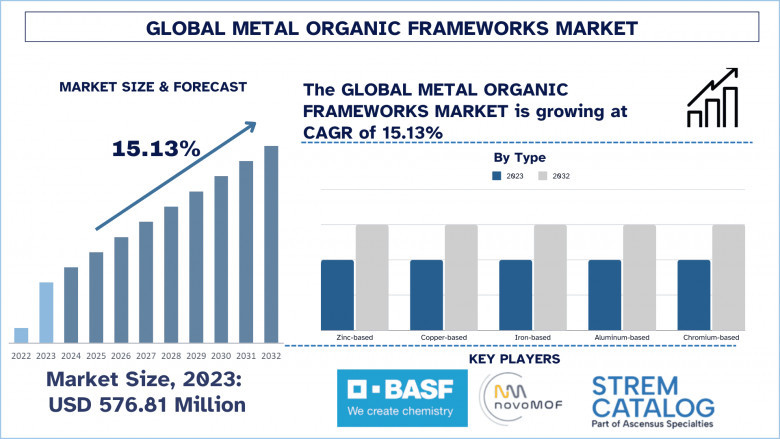

According to the UnivDatos, as per their “Metal Organic Frameworks Market” report, the global market was valued at USD 576.81 million in 2023, growing at a CAGR of about 15.13% during the forecast period from 2024-2032 to reach USD million by 2032.

The chemical company BASF SE is the world’s largest producer of its kind and is actively pursuing progress within the Metal-Organic Frameworks (MOF) market. Being focused on environmental responsibility and innovative R&D, BASF Technologies offers the MOF technology that performs even more efficiently than before in manufacturing high-performing products that cater to various industries while aiming to reduce the ecological impact.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/metal-organic-frameworks-market?popup=report-enquiry

EMBRACING SUSTAINABILITY AND TECHNOLOGICAL ADVANCEMENTS

BASF provides a wide range of MOF applications such as gas storage, catalysis, and environmental remediation. These applications are well conceived by deploying the best available technologies and practices to achieve performance, flexibility, and environmentally conscious design.

INNOVATING MOF APPLICATIONS THROUGH CUTTING-EDGE SOLUTIONS

Large-Scale MOF Production: In October 2023, BASF set the record of becoming the first company ever to commercially produce metal-organic frameworks for carbon capture at hundreds of tons per year. This will now allow the use of metal-organic frameworks in the carbon capture technology of Svante Technologies Inc. which seeks to curb CO₂ emissions produced in industry sectors such as hydrogen, pulp and paper, cement, steel, aluminum, and chemical industries.

Sustainable Packaging Initiatives: Another aspect of BASF’s initiatives towards promoting environmentally friendly usage of the MOFs is the development of the MOFs production processes that are least harmful to the environment. The company has also introduced solvent-free processes which have reduced the negative impact of the production processes on the environment and made them safer and more efficient.

Can Manufacturers Institute (CMI) and all its aluminum beverage can manufacturer and can sheet producer members endorse Mission Possible Partnership’s (MPP) transition strategy for a net-zero, 1.5°C-aligned aluminum industry. These endorsements reflect the industry’s aim to reduce the carbon footprint of the relatively small amount of primary aluminum in beverage cans, thereby contributing to the needed progress in the fight against climate change.

Collaborative Partnerships: BASF implements an active approach towards the development of the potential uses of MOFs through partnerships with various providers of technology and other companies in the industry. The cooperation with Svante Technologies Inc. demonstrates how BASF integrates its rescaling and manufacturing capabilities with the need for more effective carbon capture technology, connecting its partners and their clients with the net-zero destination.

MARKET EXPANSION AND RESEARCH INVESTMENTS

BASF continues to invest in expanding its MOF production capabilities and exploring new applications for this transformative material.

New Product Development: The research team at BASF is developing new sophistic acids with molecular level porosity design for more efficient CO₂ separation and water harvesting in the future.

Global Presence: The fabrication plants of BASF in Europe and Asia are geared to satisfy the increasing needs for those in many applications providing a strategic available supply and logistics.

Business Awards: These inventions of BASF have received numerous awards by ecological organizations for contributing to the reduction of carbon emissions and furthering sustainability.

Click here to view the Report Description & TOC: https://univdatos.com/reports/metal-organic-frameworks-market

CONCLUSION

BASF’s sustainable innovation and strategic partnerships allow the company to lead the Metal-Organic Frameworks market globally. BASF is Changing the paradigm of industries by augmenting the MOF production and expanding its applications in the clean energy, carbon capture, and environmental sectors. The initiatives of the company to produce cost-effective and high-quality solutions, which can be used for various applications, match the global trends whereby people are advocating for technologies that are clean. As gas must be stored more effectively, less gas emitted and more sustainable materials developed, BASF advancements in MOF technology will redefine the market facilitating meeting performance and environmental requirements by the industries.

Contact Us:

UnivDatos

Contact Number - +1 978 733 0253

Email - contact@univdatos.com

Website - www.univdatos.com

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany/

Comments

0 comment