Introduction

In various industries, the strength and reliability of adhesive bonds are crucial to product quality and safety. From packaging to electronics, automotive to medical applications, adhesive materials are commonly used for bonding purposes. To ensure that these adhesive bonds perform optimally under different conditions, manufacturers rely on peel strength testing equipment. One such tool is the Peel Strength Tester, a device specifically designed to assess the durability and integrity of adhesive bonds. In this article, we will delve into the importance of peel strength testing and how Pacorr's Peel Strength Tester helps manufacturers maintain high-quality standards.

What is Peel Strength Testing?

Peel strength testing is the process of measuring the force required to separate two bonded materials at a specified angle and speed. This type of test simulates real-world conditions where adhesives are exposed to peeling forces, allowing manufacturers to assess the quality and performance of adhesives and laminates.

Peel strength is a critical property for a variety of materials such as tapes, films, labels, laminates, and more. A proper test ensures that adhesives used in various products will not fail under pressure, which can prevent defects, accidents, or product failures in the end-use applications.

Applications of Peel Strength Testing

Peel strength testing Price is widely used across different industries where adhesive materials are applied. Some common applications include:

1. Packaging Industry

In packaging, adhesives are used to bond seals, labels, tapes, and other materials. A reliable bond is essential to maintain package integrity during transportation and storage. Peel strength testing ensures that packaging will not fail and compromise the product inside.

2. Automotive Industry

Adhesives in the automotive industry are used for bonding various components, such as dashboards, interiors, and trims. Ensuring these bonds can withstand environmental stress and mechanical forces is vital for vehicle durability and safety.

3. Electronics Industry

Electronics often involve bonding components like displays, batteries, or sensors. Peel strength testing ensures these bonds remain intact even when subjected to temperature variations, pressure, or mechanical impact.

4. Medical Industry

In the medical field, adhesives are frequently used in medical devices, bandages, and wound care products. These materials must perform under specific conditions without failing, making peel strength testing critical for patient safety and product efficacy.

Importance of Peel Strength Testing

Peel strength Tester Price provides valuable information that helps manufacturers optimize adhesive selection and application processes. By conducting these tests, companies can:

- Ensure product safety and reliability.

- Enhance customer satisfaction by providing durable and high-quality products.

- Avoid costly product recalls due to adhesive failures.

- Meet industry standards and regulatory requirements for adhesive performance.

- Improve overall manufacturing efficiency by minimizing production defects.

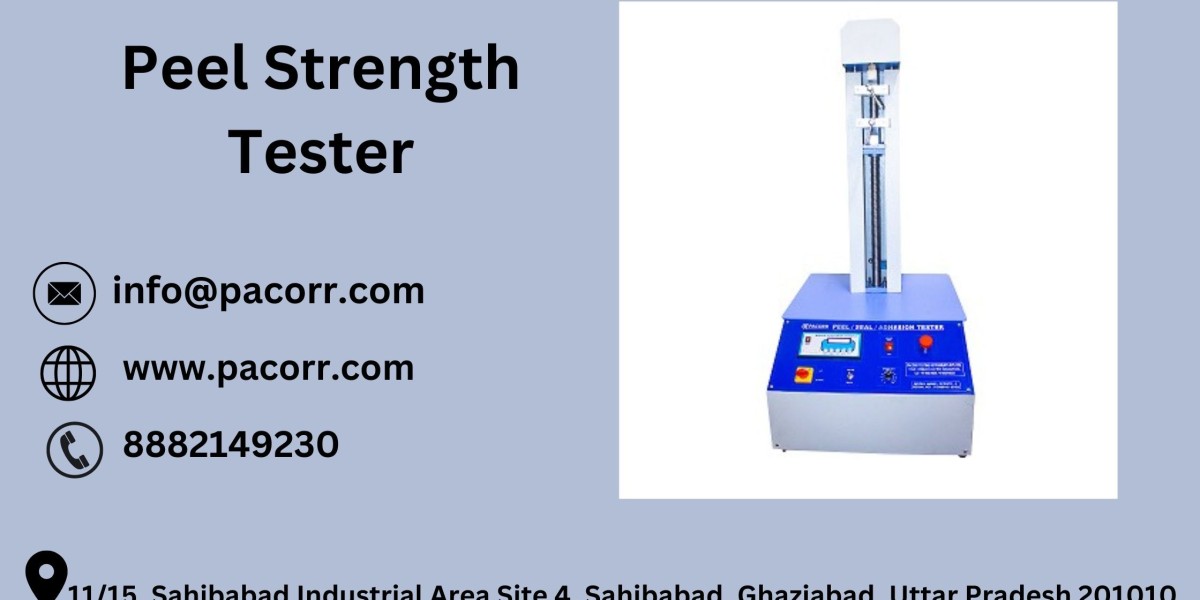

Pacorr’s Peel Strength Tester: A Benchmark of Quality

At Pacorr Testing Instruments Pvt Ltd, the Peel Strength Tester is designed with precision, accuracy, and versatility to cater to various adhesive testing requirements. The tester allows manufacturers to evaluate the performance of adhesives by simulating peel forces under controlled conditions.

Key Features of Pacorr’s Peel Strength Tester

1. High Accuracy and Consistency

The Pacorr Peel Strength Tester ensures precise measurement of peel force, helping manufacturers maintain consistent quality control across their products.

2. Customizable Testing Parameters

Pacorr's Peel Strength Tester allows users to set various parameters such as test speed, peel angle, and load capacity. This ensures that the testing conditions can be tailored to specific applications, whether it’s for packaging, automotive, or medical products.

3. User-Friendly Interface

The intuitive control panel and digital display provide easy access to data, enabling operators to efficiently conduct tests and analyze results.

4. Versatility in Applications

Whether you are testing adhesives, tapes, foils, films, or laminates, the Pacorr Peel Strength Tester Price is designed to handle a wide range of materials with varying peel properties.

5. Compliance with International Standards

Pacorr’s Peel Strength Tester complies with several international standards such as ASTM, ISO, and DIN, ensuring that your adhesive testing meets global quality benchmarks.

6. Robust Construction

Built with durable materials, Pacorr’s Peel Strength Tester is designed to withstand continuous use in industrial environments while delivering reliable performance.

Benefits of Using Pacorr’s Peel Strength Tester

- Quality Assurance: By using Pacorr’s Peel Strength Tester, manufacturers can ensure that their products adhere to the highest quality standards, enhancing consumer trust and reducing the risk of product failures.

- Cost Efficiency: Early detection of adhesive weaknesses helps manufacturers avoid costly repairs, reworks, or recalls. This leads to significant savings in production costs.

- Product Improvement: The detailed data provided by the Peel Strength Tester helps companies optimize adhesive formulations and bonding processes, leading to improved product performance.

Conclusion

In industries where adhesive performance plays a critical role in product quality and safety, peel strength testing is indispensable. By investing in reliable testing equipment such as Pacorr's Peel Strength Tester Manufacturer, manufacturers can ensure that their adhesive bonds are strong, durable, and capable of withstanding real-world conditions. This ultimately leads to better product outcomes, increased customer satisfaction, and enhanced brand reputation.

Frequently Asked Questions (FAQ) about the Peel Strength Tester

1. What is a Peel Strength Tester?

A Peel Strength Tester is a testing instrument used to measure the force required to separate two bonded materials. It helps determine the adhesive strength of tapes, films, laminates, and other adhesive-based materials.

2. Why is peel strength testing important?

Peel strength testing is essential for evaluating the performance of adhesives under specific conditions. It ensures the adhesive bonds are strong and durable, preventing product failures, defects, and safety issues in industries like packaging, automotive, electronics, and medical devices.

3. Which industries benefit from peel strength testing?

Peel Strength Tester Manufacturer is widely used in the following industries:

- Packaging (seals, tapes, and labels)

- Automotive (bonding trims and interiors)

- Electronics (bonding components like displays and sensors)

- Medical (adhesive devices like bandages and patches)

4. What materials can be tested using a Peel Strength Tester?

Materials such as adhesive tapes, foils, films, laminates, labels, and other products that require adhesive bonding can be tested using a Peel Strength Tester.

5. What parameters can be adjusted during a peel strength test?

Most peel strength testers, including Pacorr’s Peel Strength Tester, allow you to adjust the following parameters:

- Peel angle (usually 90° or 180°)

- Peel speed

- Load capacity

- Test duration

6. How does the Peel Strength Tester work?

The test specimen is clamped into the tester, and the machine applies a peeling force at a specific angle and speed. The Peel Strength Tester Supplier measures the force required to separate the bonded materials and records the result for analysis.

7. What is the difference between 90° and 180° peel tests?

- 90° peel test: The force is applied at a 90-degree angle to the surface, commonly used for rigid substrates.

- 180° peel test: The force is applied at a 180-degree angle, which is more suitable for flexible substrates and thin films.

8. What standards does the Pacorr Peel Strength Tester comply with?

Pacorr’s Peel Strength Tester is designed to comply with international standards such as:

- ASTM D903

- ISO 8510-1

- DIN 53357 These standards ensure that the test results are accurate and meet global industry requirements.

9. Can the Peel Strength Tester be used for both research and production purposes?

Yes, the Peel Strength Tester can be used for both research and production applications. It is valuable for testing in R&D labs as well as in quality control during the manufacturing process.

10. How does peel strength testing improve product quality?

Peel strength testing Price ensures that adhesives perform as expected under real-world conditions. This helps manufacturers reduce product failures, enhance durability, and improve customer satisfaction by offering high-quality products.

11. What are the key features of Pacorr’s Peel Strength Tester?

- High accuracy and consistency

- Customizable testing parameters (speed, angle, and load capacity)

- User-friendly interface with a digital display

- Compliance with international standards

- Versatile applications for different materials

- Durable construction for industrial use

12. How can I maintain my Peel Strength Tester?

Regular calibration, cleaning, and maintenance checks are important for ensuring the accuracy and longevity of your Peel Strength Tester Price Follow the manufacturer's maintenance guidelines to keep the machine in top working condition.

13. What kind of data does the Peel Strength Tester provide?

The Peel Strength Tester Supplier provides precise measurements of the peel force required to separate bonded materials, helping manufacturers evaluate the adhesive strength and durability of the product. The data can be used for quality control, product improvement, and ensuring compliance with standards.

14. Can I get training on how to use Pacorr’s Peel Strength Tester?

Yes, Pacorr offers training and support for customers to ensure proper usage of the Peel Strength Tester and to maximize the efficiency of testing operations.

15. Where can I purchase the Peel Strength Tester?

You can purchase the Peel Strength Tester directly from Pacorr Testing Instruments Pvt Ltd by visiting their website at www.pacorr.com or contacting their sales team for more details.