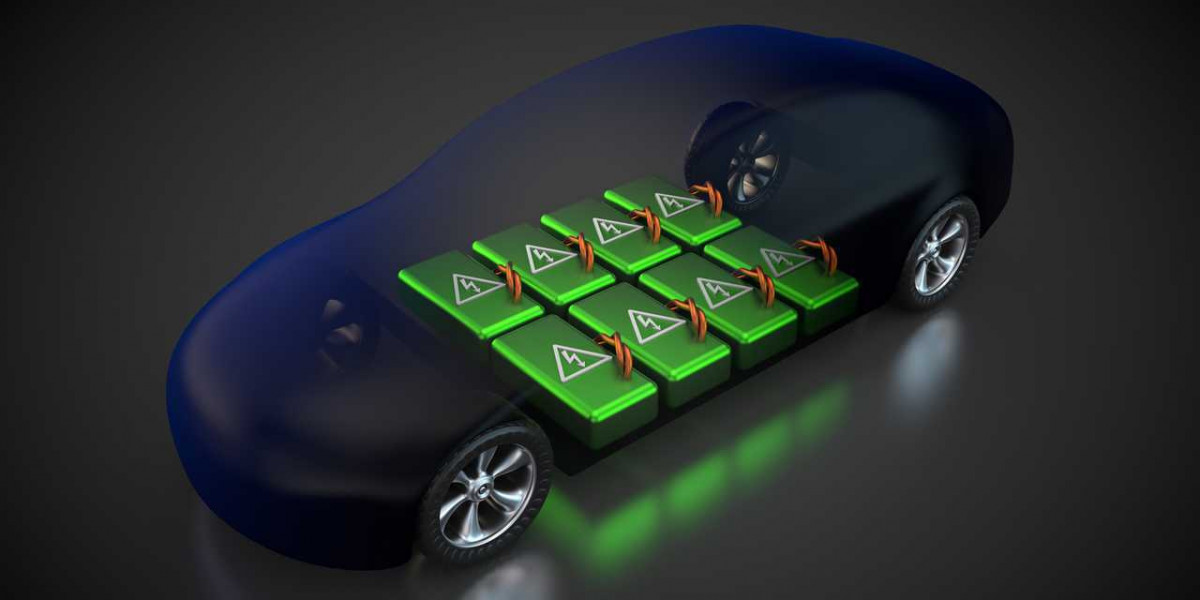

The electric vehicle (EV) industry is rapidly evolving, with significant advancements in battery technology and a global push for sustainable transportation. The electric vehicle battery adhesive market plays a critical role in the successful deployment of EVs, as these adhesives are integral in ensuring the structural integrity, safety, and performance of battery systems. This article explores the key market dynamics shaping the growth of the electric vehicle battery adhesive market.

Market Drivers

Increase in Electric Vehicle Adoption

The growing adoption of electric vehicles worldwide is a major driver for the electric vehicle battery adhesive market. As more consumers and businesses shift to EVs, the demand for robust, efficient, and safe battery systems intensifies, further driving the need for high-performance adhesives in EV battery assemblies.Technological Advancements in Batteries

Innovation in battery technologies, such as solid-state batteries and lithium-ion improvements, requires adhesives that offer enhanced thermal management, electrical insulation, and durability. These advancements are pushing the boundaries of adhesive formulations, fueling growth in the electric vehicle battery adhesive market.Growing Focus on Lightweight Materials

Automakers are increasingly using lightweight materials in vehicle construction to improve energy efficiency and range. Battery adhesives offer a lightweight alternative to traditional fasteners and help reduce the overall weight of EV battery packs, making them an attractive solution in vehicle design and production.Regulatory Pressures for Lower Emissions

Governments worldwide are imposing stricter emissions regulations, encouraging the transition to electric vehicles. This regulatory shift is a key driver of demand for EVs and subsequently, for the materials that make up the battery systems, including adhesives. Policies and incentives that promote electric mobility are further stimulating the growth of the electric vehicle battery adhesive market.Enhanced Safety Requirements

Safety is a paramount concern in electric vehicle design, especially for battery systems that are susceptible to overheating and thermal runaway. Adhesives with enhanced fire resistance, impact absorption, and shock resistance are in high demand to ensure that EV batteries perform safely under extreme conditions. These safety requirements contribute to the rising demand for advanced battery adhesives.

Market Challenges

High Cost of Advanced Adhesives

High-performance adhesives designed to meet the complex requirements of EV battery systems are often more expensive than conventional alternatives. This cost factor can be a challenge for automakers who need to balance cost with quality and performance, especially as the EV market continues to mature.Material Compatibility Issues

Different battery chemistries and materials require adhesives with specific properties. Ensuring compatibility between adhesives and a wide range of battery components is challenging and requires extensive testing and development. Any incompatibility could affect the long-term performance of the battery pack, making material compatibility a critical issue for adhesive manufacturers.Regulatory Compliance and Safety Standards

The electric vehicle battery adhesive market faces complex regulatory challenges. Adhesives used in battery applications must meet stringent safety and environmental standards, which vary across regions. Manufacturers must invest in ensuring that their products comply with global regulations, including those governing fire safety, toxicity, and environmental impact.Supply Chain Constraints

The global supply chain for raw materials used in adhesives is vulnerable to disruptions, which can affect the availability and cost of critical components. Any delays or shortages in raw materials could impact the production and availability of adhesives, potentially hindering the growth of the electric vehicle battery adhesive market.

Market Opportunities

Growing Demand for Sustainable Adhesives

There is an increasing push for sustainability in the automotive industry, and the electric vehicle battery adhesive market is no exception. Eco-friendly adhesives made from renewable materials are gaining popularity as automakers aim to reduce their carbon footprint. This trend opens up opportunities for adhesive manufacturers to develop sustainable alternatives to conventional products.Collaborations Between Automakers and Adhesive Suppliers

Collaborations and partnerships between adhesive suppliers and automakers are becoming more common as both parties work together to develop adhesive solutions that meet the evolving needs of EV battery systems. These partnerships provide opportunities for innovation and the creation of tailored adhesive solutions that meet specific requirements.Advancements in Automation and Manufacturing Technologies

With the growing demand for EVs, manufacturers are adopting automation and advanced manufacturing technologies to streamline production processes. Automated systems allow for more precise and efficient application of adhesives in battery manufacturing, improving product consistency and reducing waste. This trend presents an opportunity for adhesive companies to invest in automation solutions for their production lines.Rising Demand for Fast-Curing Adhesives

As the need for faster production times grows, manufacturers are increasingly seeking fast-curing adhesives that can speed up the assembly process. The demand for adhesives with rapid curing times is creating opportunities for innovation in adhesive formulations, benefiting both manufacturers and adhesive suppliers.Emerging Markets in Developing Regions

Developing regions, particularly in Asia-Pacific, Africa, and Latin America, are witnessing a rise in the adoption of electric vehicles. With the increasing urbanization and focus on sustainable mobility, these regions present a significant growth opportunity for the electric vehicle battery adhesive market. As local manufacturing capabilities improve, the demand for battery adhesives in these regions is expected to rise.