The electronics adhesives market is experiencing continuous growth due to increasing demand for efficient and durable bonding solutions in the electronics sector. The market is witnessing strategic moves that are reshaping the industry landscape. Companies are adopting various strategies such as mergers, acquisitions, product innovations, and geographical expansions to capture a larger market share and strengthen their position in this competitive space.

Product Innovation and Diversification

- Companies are heavily investing in research and development (RD) to introduce new products that cater to the evolving needs of the electronics industry.

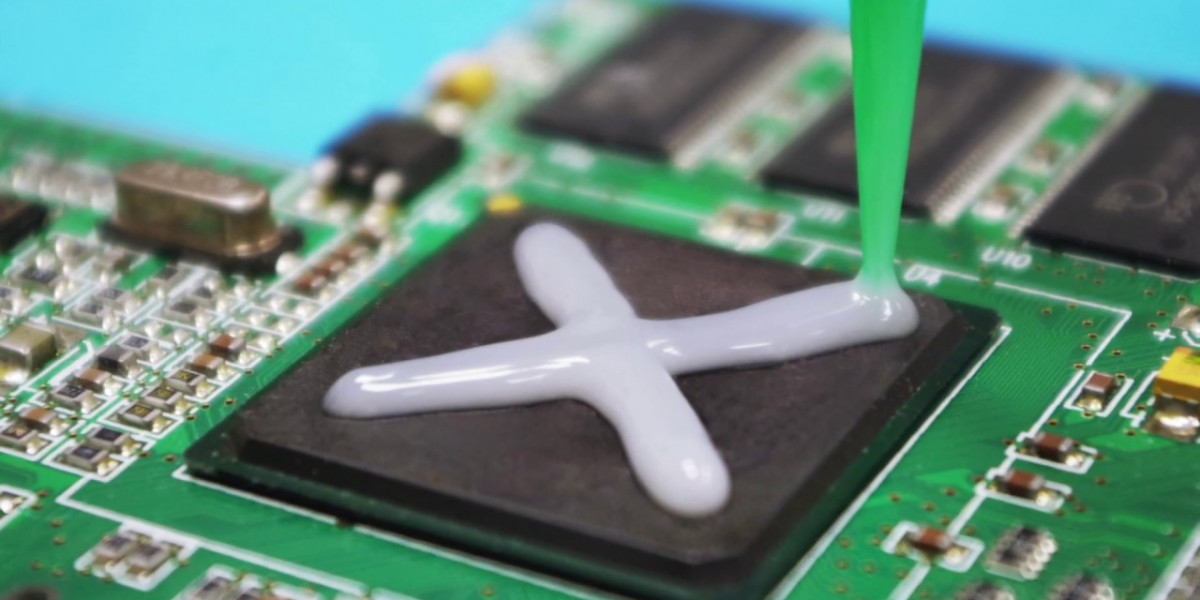

- Advanced adhesives that offer superior performance in terms of heat resistance, conductivity, and flexibility are gaining traction.

- There is a growing trend towards eco-friendly, sustainable adhesive solutions, in response to increasing environmental regulations and consumer preference for green products.

- High-performance adhesives for use in small and intricate electronic devices, such as smartphones and wearables, are becoming increasingly popular.

Acquisitions and Mergers to Expand Product Portfolio

- Several players in the electronics adhesives market are focusing on strategic acquisitions and mergers to expand their product offerings and enter new markets.

- This approach enables companies to leverage the technologies, resources, and customer bases of the acquired firms.

- Mergers and acquisitions also help organizations to diversify their adhesive product lines and increase their technological capabilities in specialized areas such as conductive adhesives and UV-cured adhesives.

- As a result, companies gain a competitive edge by offering comprehensive solutions that address a wider range of consumer needs.

Geographical Expansion to Tap Emerging Markets

- Major players in the electronics adhesives market are increasingly focusing on expanding their presence in emerging markets.

- Growing industrialization and the rise of the electronics manufacturing sector in regions such as Asia-Pacific and Latin America present lucrative opportunities.

- Regional expansion helps companies tap into new customer bases, enhancing their market reach and improving sales volumes.

- Additionally, it allows companies to optimize production processes by setting up manufacturing plants closer to key markets, reducing shipping costs and lead times.

Strategic Partnerships with Electronics Manufacturers

- To gain market share and strengthen their product offerings, adhesive manufacturers are forming strategic partnerships with prominent electronics manufacturers.

- These collaborations allow for the development of customized adhesive solutions tailored to the specific needs of various electronic devices and components.

- By working closely with electronics manufacturers, companies can align their adhesive solutions with the latest trends in the industry, such as miniaturization and the need for more efficient assembly processes.

- Collaborative efforts also foster mutual growth and enable companies to stay ahead in a highly competitive market.

Focus on Sustainability and Eco-Friendly Solutions

- With growing concerns about environmental impact, companies in the electronics adhesives market are prioritizing sustainability.

- There is a rising demand for adhesives that are free from harmful chemicals and can be safely disposed of or recycled.

- Manufacturers are focusing on the development of bio-based and low-VOC adhesives that comply with global environmental standards.

- These sustainability-driven initiatives not only cater to regulatory requirements but also appeal to environmentally conscious consumers and companies looking to reduce their carbon footprints.

Cost-Effective Production and Supply Chain Optimization

- In an effort to increase profitability, electronics adhesives companies are implementing cost-effective production methods and optimizing their supply chains.

- Automation and advanced manufacturing techniques are being adopted to reduce production costs and improve efficiency.

- Companies are also focusing on enhancing supply chain resilience by diversifying suppliers and improving logistics management.

- This ensures that production is not disrupted by external factors, such as geopolitical instability or raw material shortages, while also maintaining a competitive pricing structure.

Focus on End-User Applications and Market Segmentation

- Companies are increasingly focusing on specific end-user applications in the electronics adhesives market to better cater to diverse industry needs.

- Market segmentation based on applications, such as consumer electronics, automotive electronics, and industrial electronics, enables manufacturers to target key customers more effectively.

- Tailored adhesive solutions for various applications allow companies to increase their market share by offering specialized products for different niches.

- This strategic move also helps manufacturers build a stronger brand reputation in their targeted markets.

Adoption of Smart Technologies for Adhesive Applications

- The integration of smart technologies, such as sensors and conductive adhesives, into electronic products is becoming a key trend.

- Electronics adhesives are being developed with embedded smart functionalities, such as temperature sensors or touch-sensitive properties, to enhance product performance.

- Manufacturers are also exploring the use of adhesives in wearable devices, medical electronics, and IoT (Internet of Things) applications to cater to the rising demand for smart and connected devices.