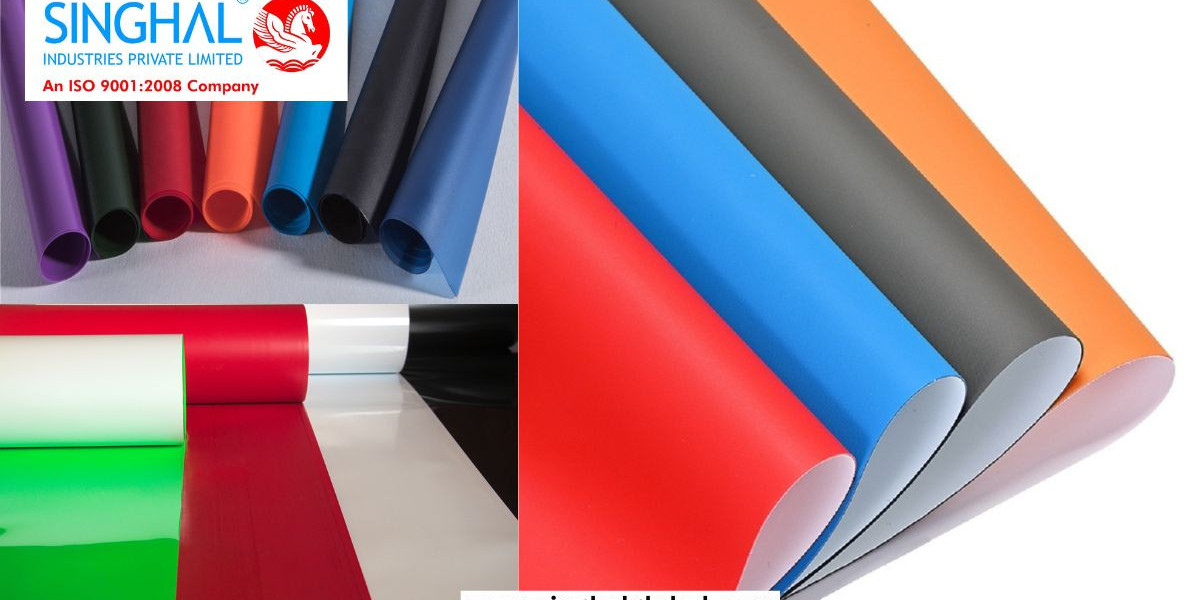

Thermoplastic Polyurethane (TPU) film has become an essential material in a wide range of industries due to its unique properties. Known for its excellent elasticity, durability, and resistance to wear, TPU film is used in everything from medical devices to automotive applications, as well as packaging, sports equipment, and footwear. With growing demand, TPU film manufacturers in Ahmedabad, TPU film manufacturers in India, and TPU film roll exporters in Ahmedabad are providing high-quality solutions to meet the needs of these diverse industries.

In this article, we will explore what TPU film is, its benefits, its applications, and the key role that TPU film manufacturers in Ahmedabad and other manufacturers across India play in meeting the demand for this versatile material.

What is TPU Film?

TPU film is a thin, flexible sheet made from thermoplastic polyurethane, a polymer known for its exceptional combination of properties. Unlike traditional plastic films, TPU film offers superior abrasion resistance, high tensile strength, and flexibility. These qualities make it suitable for both protective and functional purposes.

TPU is a versatile material that can be processed in a variety of forms, including films, sheets, and coatings. It is produced through a process that involves the polymerization of a combination of diisocyanates and polyols, which creates a material with a high level of elasticity and durability.

Key Benefits of TPU Film

Durability and Abrasion Resistance: TPU film is highly durable, offering excellent resistance to wear, tear, and abrasion. This makes it ideal for applications where the material will be exposed to constant friction or contact with rough surfaces.

Elasticity and Flexibility: TPU film maintains a high level of flexibility, even in low temperatures. It can be stretched and bent without cracking, making it ideal for products that require a combination of flexibility and strength.

Chemical and Oil Resistance: TPU film is resistant to oils, greases, and various chemicals, making it a popular choice for industrial applications where exposure to these substances is common.

High Transparency: TPU film is naturally transparent, making it a preferred option for applications that require visibility, such as protective films or packaging.

Eco-Friendly: TPU is considered more environmentally friendly than other plastic materials because it is fully recyclable. Additionally, it is free from harmful substances like BPA, making it a safer alternative for various uses.

UV and Weather Resistance: TPU films exhibit excellent resistance to UV radiation and environmental weathering, ensuring long-lasting performance even in outdoor conditions.

Thermoplastic Properties: As a thermoplastic material, TPU film can be molded and remolded multiple times when heated, making it versatile for a variety of manufacturing processes.

Applications of TPU Film

Due to its superior properties, TPU film is used across various industries. Some of the most common applications include:

Automotive Industry: In the automotive sector, TPU films are used for applications such as protective covers, seat upholstery, airbags, and window films. The durability and resistance to oils and chemicals make it ideal for use in harsh automotive environments.

Medical Devices: TPU film is widely used in the medical industry due to its biocompatibility, flexibility, and resistance to sterilization methods. It is used in products such as catheters, wound dressings, and surgical drapes.

Footwear: TPU film is commonly used in the footwear industry for applications like soles, uppers, and waterproofing layers. Its durability, flexibility, and resistance to abrasion make it an ideal choice for high-performance footwear.

Packaging: In the packaging industry, TPU film is used for creating flexible, transparent packaging materials. It provides a combination of durability, elasticity, and transparency, making it ideal for food packaging, electronics, and cosmetics.

Sports Equipment: TPU film is used in the production of sports equipment, such as inflatable sports products, protective gear, and other gear that requires a combination of flexibility, strength, and resistance to wear and tear.

Textiles: TPU films are used as a protective coating for textiles, offering benefits like waterproofing, abrasion resistance, and flexibility. It is commonly used in outdoor apparel, tents, and other textiles exposed to the elements.

Electronics: TPU film is also used in electronics for protective covers, insulation, and screens, particularly for devices that require flexibility and durability without compromising performance.

Role of TPU Film Manufacturers in India

The global demand for TPU film has led to significant growth in the production of this material in India. TPU film manufacturers in India are playing a vital role in meeting both domestic and international requirements. Manufacturers in Ahmedabad, in particular, are contributing significantly to this growth. TPU film manufacturers in Ahmedabad are known for their ability to provide high-quality TPU films that meet a wide range of industry standards.

Ahmedabad is a hub for manufacturing and exporting TPU film products, and many manufacturers in the region specialize in producing custom TPU films to suit the unique needs of various industries. These manufacturers are equipped with advanced machinery and have access to high-quality raw materials, ensuring that the products they create are of the highest standards.

Moreover, TPU film roll exporters in Ahmedabad are playing an essential role in expanding India’s presence in the global market. These exporters are not only focusing on meeting the domestic demand for TPU film but are also supplying this versatile material to international markets, thereby boosting India’s export potential.

FAQs

1. What are the main advantages of using TPU film over other materials?

TPU film offers several advantages, including excellent durability, flexibility, abrasion resistance, and chemical resistance. Unlike other materials, TPU film remains flexible even in low temperatures and can be used in harsh conditions without compromising its performance. Its eco-friendly properties and recyclability also make it a more sustainable option.

2. Is TPU film suitable for medical applications?

Yes, TPU film is widely used in medical applications due to its biocompatibility, flexibility, and resistance to sterilization methods. It is commonly used in products such as catheters, wound dressings, and surgical drapes, where safety and reliability are paramount.

3. How is TPU film processed during manufacturing?

TPU film is manufactured through a thermoplastic extrusion process, where TPU pellets are melted and extruded into thin films. These films are then cooled, wound into rolls, and can be further processed to meet the specific needs of different industries. The manufacturing process can be customized to create films of various thicknesses, widths, and properties.