The machine safety market is rapidly growing due to increasing industrialization and the need to ensure workplace safety. With more automation in various sectors, machine safety has become a critical focus for industries worldwide. As companies look to enhance productivity while minimizing risks, the demand for machine safety solutions continues to rise. This market includes the development and implementation of technologies that help prevent accidents, ensure compliance with safety regulations, and protect both operators and machinery. The demand for advanced machine safety solutions is driven by several factors that cater to the evolving industrial landscape, including strict government regulations, technological advancements, and rising awareness about worker safety.

Key Factors Driving Market Demand

1. Stringent Government Regulations

Governments across the globe are implementing stricter regulations regarding workplace safety. These regulations mandate industries to adopt safety standards to prevent accidents and injuries. Countries like the United States, Germany, and Japan are leading the way in enforcing machine safety guidelines. The rise in regulatory compliance requirements directly contributes to the growing demand for machine safety products and services. As industries aim to comply with these regulations, they invest in safety technologies to avoid penalties and reduce liability risks.

2. Technological Advancements in Machine Safety

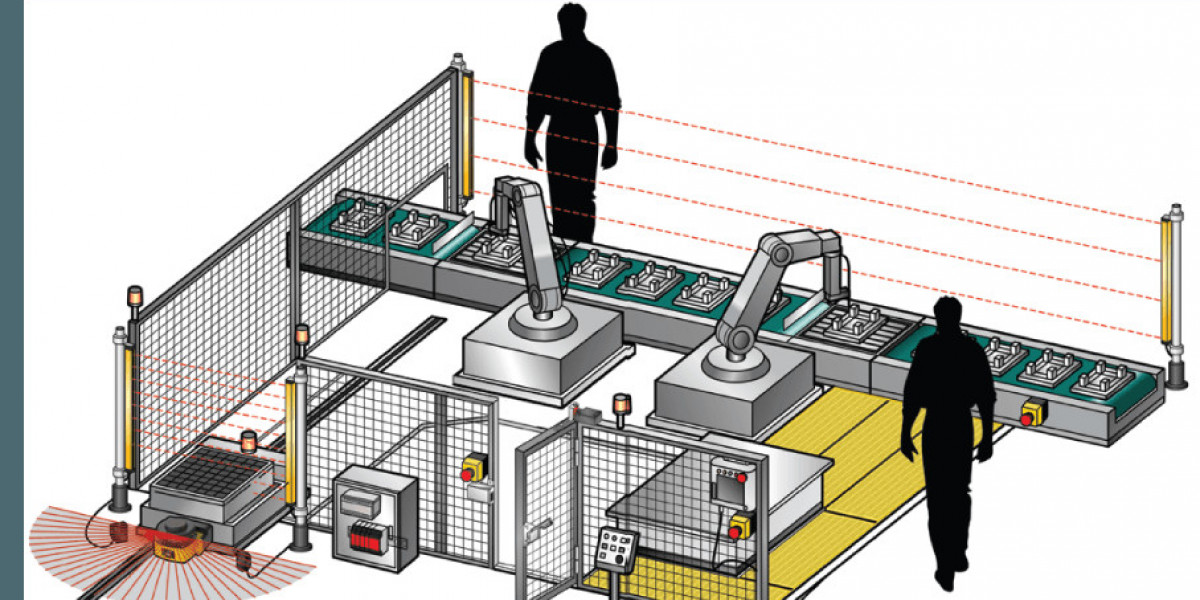

Advancements in technology play a significant role in shaping the machine safety market. With the integration of automation, robotics, and artificial intelligence (AI) in industries, the need for sophisticated safety solutions has increased. Machine safety equipment is becoming more advanced, offering features like real-time monitoring, predictive maintenance, and enhanced data analytics. These innovations not only improve safety but also optimize machine performance, further driving demand for cutting-edge safety technologies.

3. Growing Awareness About Worker Safety

As workers' safety becomes a more significant concern, businesses are focusing more on creating safer work environments. Increased awareness about workplace accidents and their impact on productivity and employee well-being has led to a surge in the demand for machine safety solutions. Companies are now more proactive in adopting safety protocols to protect their workforce. This heightened awareness ensures that industries prioritize safety, which is fueling the growth of the machine safety market.

4. Increased Automation and Industry 4.0 Integration

The ongoing trend of automation in manufacturing and other industries is significantly boosting the demand for machine safety systems. As production lines become more automated, machines require advanced safety protocols to prevent accidents. Industry 4.0, which involves the use of IoT, smart devices, and real-time data processing, has created a higher demand for machine safety solutions. These systems need to be more sophisticated to integrate seamlessly with automated processes, enhancing their effectiveness in preventing accidents and improving operational efficiency.

5. Rising Focus on Productivity and Operational Efficiency

Machine safety is not only about preventing accidents; it also plays a role in improving productivity and operational efficiency. By ensuring that machines operate safely without interruptions or accidents, companies can maintain continuous production cycles and reduce downtime. As industries strive for higher productivity, they are increasingly adopting machine safety solutions that guarantee smooth and efficient operations, contributing to the market’s expansion.

6. Demand from Emerging Economies

Emerging economies in Asia-Pacific, Latin America, and the Middle East are becoming significant contributors to the growth of the machine safety market. These regions are experiencing rapid industrialization, and businesses are recognizing the importance of incorporating safety measures in their operations. Governments in these regions are also introducing regulations to improve safety standards, thus spurring the demand for machine safety technologies. This demand is expected to grow exponentially in the coming years as these regions continue to develop industrially.

7. The Importance of Preventive Maintenance

Preventive maintenance is another key driver of the machine safety market. As industries look for ways to reduce maintenance costs and avoid machine breakdowns, preventive maintenance strategies are being increasingly adopted. By using safety solutions that monitor equipment health and performance, companies can predict potential failures before they occur. This not only ensures safety but also enhances the longevity of machinery and reduces operational disruptions, boosting the demand for safety solutions.

8. Impact of Workplace Accidents on Business

Workplace accidents can have severe consequences for businesses, including legal liabilities, compensation costs, and damage to reputation. As companies aim to avoid these repercussions, the demand for machine safety solutions has grown. By investing in safety technologies, businesses can significantly reduce the risk of accidents and avoid the financial and operational costs associated with workplace injuries. This factor is especially important in high-risk industries such as manufacturing, automotive, and construction.

9. Market Demand from Industrial Sectors

Key industrial sectors such as manufacturing, automotive, and oil and gas have the highest demand for machine safety solutions. These industries involve heavy machinery and equipment, making safety a top priority. As industrial sectors expand, the need for reliable machine safety products becomes even more critical. Companies in these sectors are focusing on implementing safety measures that not only comply with regulations but also enhance operational efficiency.

10. Growing Focus on Data Security

Data security has become a significant concern in machine safety systems, especially with the increased connectivity and integration of machines in the industrial Internet of Things (IoT). Securing data from machine safety devices and sensors is crucial to maintaining operational integrity and preventing cyber-attacks. As the focus on cybersecurity increases, companies are seeking machine safety solutions that also provide strong data protection, further boosting the demand for these products.