The 3D printing stainless steel market is experiencing remarkable growth due to the increasing demand for advanced manufacturing solutions. Stainless steel's durability, corrosion resistance, and high strength make it an ideal material for producing complex and functional parts. Industries like aerospace, automotive, and healthcare are driving the adoption of 3D printing technology, resulting in streamlined production processes and reduced material waste.

Key Growth Drivers

Rising investments in additive manufacturing technologies are accelerating the market's expansion. Companies are leveraging stainless steel 3D printing for prototyping, tooling, and end-use part production. Additionally, the growing emphasis on sustainable manufacturing and reduced carbon footprints has made 3D printing a preferred choice for several industries. Enhanced design flexibility, rapid prototyping capabilities, and reduced lead times further contribute to its widespread adoption.

Technological Advancements

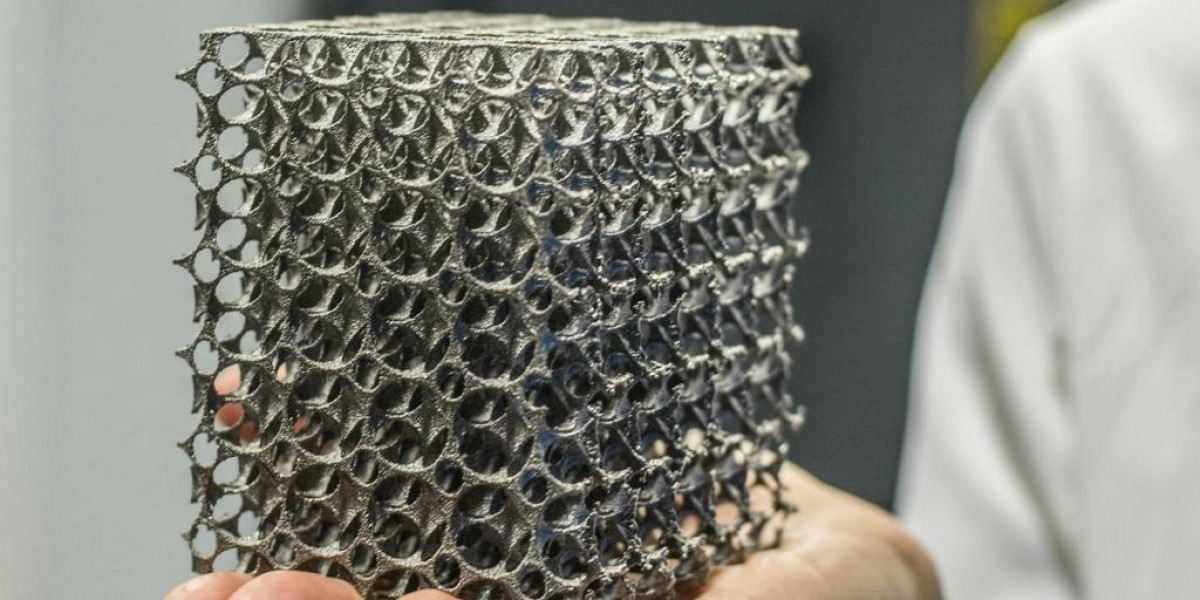

Significant advancements in printing technologies, such as laser powder bed fusion (LPBF) and directed energy deposition (DED), have revolutionized stainless steel 3D printing. These technologies ensure precise layer-by-layer construction, resulting in high-performance parts with complex geometries. Innovations in metal powders and post-processing techniques also contribute to improved material properties, enabling the production of components that meet stringent industry standards.

Applications Across Industries

Aerospace manufacturers are utilizing stainless steel 3D printing for producing lightweight, high-strength components. The automotive industry benefits from its capability to produce intricate engine parts and customized designs. Additionally, the healthcare sector has embraced 3D printing for creating medical implants, surgical instruments, and patient-specific devices. This versatility makes stainless steel 3D printing a valuable solution across diverse sectors.

Regional Insights

North America and Europe dominate the market, supported by the presence of established additive manufacturing companies and research institutions. Asia-Pacific is witnessing significant growth, driven by increasing industrialization, government initiatives, and technological advancements. Countries like China, Japan, and South Korea are rapidly adopting 3D printing for industrial applications, contributing to regional market growth.

Challenges and Opportunities

While the market offers numerous opportunities, challenges such as high initial investment costs and technical complexities remain. Companies are addressing these issues by developing cost-effective solutions and offering comprehensive training programs. The ongoing development of new stainless steel alloys and enhanced printing techniques is also expected to mitigate these challenges, providing growth opportunities in the coming years.

Future Outlook

The future of the stainless steel 3D printing market looks promising, with continuous advancements in technology and material science. Collaborative partnerships between manufacturers, research institutions, and technology providers will further accelerate innovation. As sustainability becomes a priority, the adoption of eco-friendly and recyclable stainless steel powders will enhance the market's growth. Companies investing in automation and digital manufacturing will gain a competitive edge, ensuring the long-term success of stainless steel 3D printing solutions.

Conclusion

The 3D printing stainless steel market is poised for substantial growth, fueled by technological advancements and the increasing need for efficient manufacturing solutions. Its applications across aerospace, automotive, and healthcare industries continue to expand, offering significant opportunities for businesses and manufacturers. With innovations in printing processes and material development, stainless steel 3D printing will remain a key player in the evolving landscape of additive manufacturing.