The global COVID-19 pandemic has disrupted industries across the world, causing unprecedented challenges in manufacturing, logistics, and supply chain management. However, it has also accelerated the adoption of collaborative robots market as businesses seek ways to adapt to new operational requirements, improve efficiency, and mitigate risks. Cobots, designed to work alongside humans in a safe and flexible manner, have proven to be an essential solution for companies navigating the complexities of the pandemic and supply chain disruptions.

Disruptions in the Supply Chain

One of the most significant impacts of the COVID-19 pandemic has been the disruption of global supply chains. Lockdowns, restrictions on international trade, and factory closures led to delays in production and shortages of critical components across many industries. These disruptions forced companies to rethink their manufacturing processes and adopt technologies that would help reduce dependency on human labor and improve flexibility in operations.

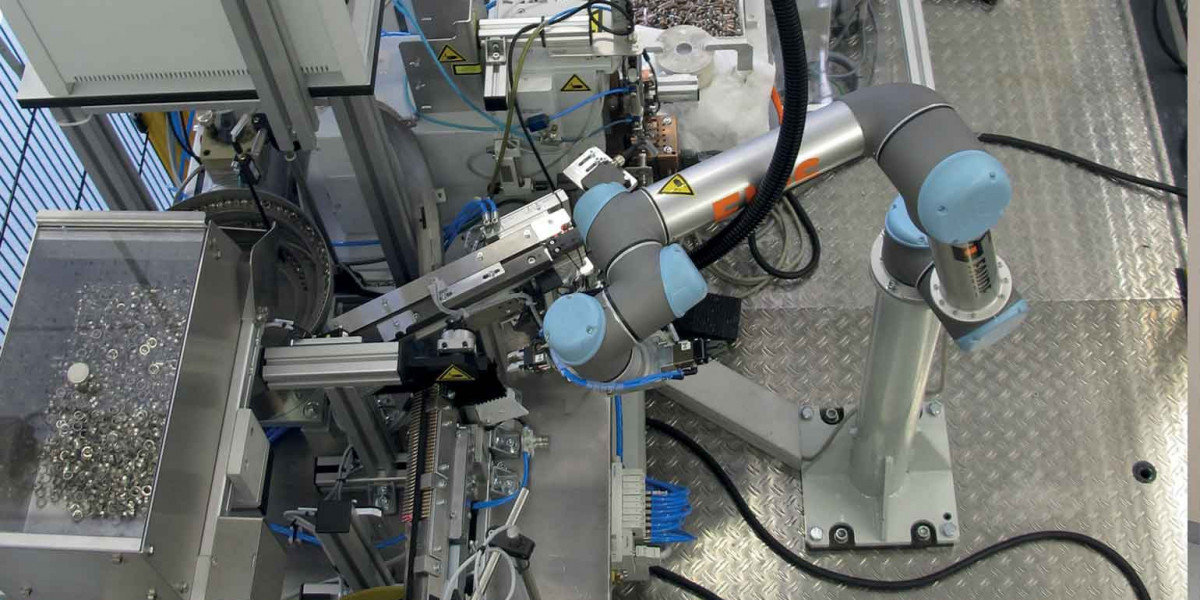

Cobots emerged as a crucial solution to these challenges. Their ability to operate safely alongside human workers allowed businesses to maintain operations despite the physical distancing measures required during the pandemic. Cobots were particularly useful in areas where labor shortages were most pronounced, as many workers were either furloughed or unable to work due to health concerns. With cobots performing repetitive and hazardous tasks, companies could reduce the risk of exposure while maintaining productivity.

Acceleration of Automation Adoption

The pandemic highlighted the vulnerabilities of traditional manufacturing and supply chain models, where a high reliance on human labor and just-in-time inventory systems created risks of production halts. In response, many companies accelerated their adoption of automation technologies, including collaborative robots, to mitigate these risks in the future.

Cobots are particularly well-suited for industries that require flexibility and rapid adjustments to changing conditions, such as electronics, food and beverage, and e-commerce. During the pandemic, these sectors saw a surge in demand, and cobots helped businesses scale their operations quickly to meet this increased demand. For example, cobots were used in e-commerce warehouses to assist with picking, packing, and sorting, reducing the need for human labor and minimizing the impact of supply chain delays.

Enhancing Workforce Resilience

The pandemic underscored the importance of building resilient and adaptable workforces. Cobots have proven to be a key enabler of this resilience by allowing businesses to maintain operations even when faced with disruptions like labor shortages and social distancing measures. Unlike traditional robots, which often require dedicated spaces and safety barriers, cobots are designed to work alongside human operators without the need for extensive modifications to the workspace.

This collaborative approach ensures that human workers can focus on more complex tasks, while cobots handle repetitive, manual jobs. As a result, businesses have been able to reduce worker fatigue and improve safety in the workplace, which became even more critical during the pandemic.

Long-Term Impact and Future Trends

While the immediate effects of the COVID-19 pandemic caused significant disruptions, it has also led to lasting changes in the way businesses approach automation. The need for greater flexibility, increased safety, and workforce resilience will likely continue driving demand for cobots in the post-pandemic world.

In the future, businesses will focus on improving their supply chain resilience by adopting more agile manufacturing processes, supported by cobots and other automation technologies. Additionally, advancements in artificial intelligence (AI), machine learning, and sensor technologies will make cobots even more versatile and capable of performing a broader range of tasks.

The COVID-19 pandemic also highlighted the importance of diversifying supply chains and increasing local production capabilities. This trend is likely to fuel the growth of cobots in regional manufacturing hubs, where businesses can quickly adapt to shifting demand and mitigate the risks associated with global supply chain disruptions.

Conclusion

The COVID-19 pandemic has had a profound impact on industries worldwide, disrupting supply chains and forcing businesses to rethink their operations. Collaborative robots have emerged as a critical solution during this time, enabling companies to maintain productivity, ensure worker safety, and reduce dependence on human labor. As the world recovers from the pandemic, the trend toward automation, particularly in the form of cobots, is expected to continue growing. With increased resilience, efficiency, and flexibility, cobots are poised to play a pivotal role in shaping the future of manufacturing and supply chain operations.