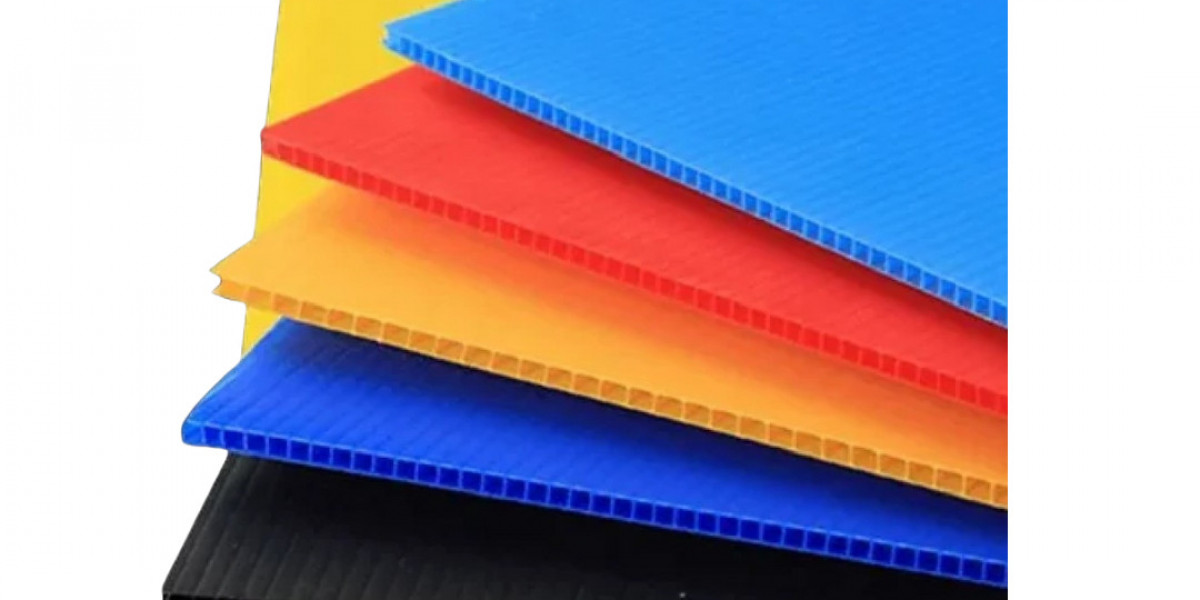

Among the myriad of options available, the rigid polypropylene (PP) corrugated sheet stands out as a testament to engineering ingenuity. Its unique structure, characterized by a series of parallel flutes or ribs, grants it an exceptional strength-to-weight ratio, making it a preferred choice for a multitude of applications. This material's intrinsic properties, including chemical resistance, impact resilience, and weatherability, position it as a formidable barrier and a holistic industrial solution. The genesis of such a material, especially within the dynamic industrial environment of nations like India, where adaptability and cost-effectiveness are paramount, highlights the critical role of specialized manufacturers. The search for a reliable Pp Corrugated Sheet Manufacturer In India often leads to discovering innovative solutions tailored to specific regional needs, demonstrating the material's widespread acceptance and utility.

The Architectural Alchemy: Constructing Form and Function with PP Corrugated Sheets

Delving deeper into the structural integrity of rigid PP corrugated sheets reveals a marvel of design. The fluted construction, reminiscent of ancient architectural principles, provides significant reinforcement without adding excessive weight. This design effectively distributes stress across the sheet, preventing buckling and deformation under load. This characteristic is particularly advantageous in applications requiring structural support, such as packaging, signage, and temporary shelters. The ability to customize the sheet's thickness, flute direction, and overall dimensions allows for tailored solutions that meet precise engineering requirements. Furthermore, the material's inherent flexibility allows it to be formed into complex shapes, enabling its use in diverse applications ranging from automotive components to agricultural structures. The increasing demand for such versatile materials has prompted a surge in the number of Pp Corrugated Sheet Manufacture Near Me, indicating a growing awareness of the material's potential and its accessibility.

The Chemical Citadel: Resisting the Elements with PP's Intrinsic Properties

One of the most compelling attributes of rigid PP corrugated sheets is their exceptional chemical resistance. Polypropylene, a thermoplastic polymer, is inherently inert to a wide range of chemicals, including acids, alkalis, and solvents. This property makes it ideal for use in environments where exposure to corrosive substances is a concern, such as chemical processing plants, 1 laboratories, and waste treatment facilities. The material's resistance to moisture and UV radiation further enhances its durability, ensuring a long service life even in harsh outdoor conditions. This resilience to environmental factors is crucial for applications where longevity and reliability are paramount, such as in the construction of outdoor signage, protective barriers, and agricultural covers. Understanding the Pp Corrugated Sheet Price In India becomes essential for industries aiming to balance material quality with cost-effectiveness.

The Impact Imperative: Absorbing and Diffusing Kinetic Energy

The ability of rigid PP corrugated sheets to absorb and diffuse impact energy is another critical characteristic that contributes to their widespread adoption. The fluted structure acts as a series of miniature shock absorbers, dissipating kinetic energy and preventing damage to the material itself or to the objects it protects. This property is particularly valuable in packaging applications, where it safeguards fragile goods during transportation and handling. The material's impact resistance also makes it suitable for use in protective barriers, such as temporary walls and safety shields, where it can absorb the force of collisions and prevent injuries. The increasing safety standards across industries have driven the need for such impact-resistant materials, making PP corrugated sheets a preferred choice for many manufacturers.

The Thermal Tenacity: Enduring Temperature Fluctuations with Polypropylene

Polypropylene's thermal stability is another significant advantage, allowing rigid PP corrugated sheets to withstand a wide range of temperatures without significant degradation. This characteristic is crucial for applications where the material is exposed to extreme heat or cold, such as in automotive components, industrial enclosures, and outdoor structures. The ability to maintain its structural integrity and mechanical properties across varying temperatures ensures reliable performance in diverse environments. This thermal resilience, combined with its chemical resistance and impact strength, makes PP corrugated sheets a versatile material for a broad spectrum of industrial applications. The demand for materials that can withstand extreme conditions has heightened the focus on finding a suitable Pp Corrugated Sheet Manufacturer In India capable of providing consistent quality.

The Sustainable Stratagem: Embracing Recyclability and Environmental Consciousness

In an era of increasing environmental awareness, the recyclability of rigid PP corrugated sheets is a significant advantage. Polypropylene is a thermoplastic polymer that can be melted and remolded multiple times without significant degradation, allowing for efficient recycling and reuse. This recyclability reduces waste and minimizes the environmental impact of industrial processes. The material's lightweight nature also contributes to sustainability by reducing fuel consumption during transportation. The growing emphasis on sustainable practices has prompted industries to seek materials that align with their environmental goals, making PP corrugated sheets a preferred choice for eco-conscious manufacturers. The search for a Pp Corrugated Sheet Manufacture Near Me often includes considerations for the manufacturer's environmental policies and recycling practices.

The Versatile Vanguard: Applications Across Diverse Industries

The versatility of rigid PP corrugated sheets extends across a wide range of industries, from packaging and signage to construction and agriculture. In packaging, it is used to create protective containers, dividers, and layer pads that safeguard fragile goods during transport. In signage, it provides a lightweight and durable substrate for outdoor displays, advertising boards, and directional signs. In construction, it is used for temporary walls, formwork, and protective barriers. In agriculture, it serves as greenhouse panels, plant protectors, and livestock enclosures. This diverse range of applications underscores the material's adaptability and its ability to meet the specific needs of different industries. The Pp Corrugated Sheet Price In India varies based on these varied applications and the specific customization the product needs.

The Economic Equation: Balancing Cost and Performance

The economic advantages of rigid PP corrugated sheets are another compelling factor contributing to their widespread adoption. Compared to traditional materials like wood, metal, and cardboard, PP corrugated sheets offer a lower cost per unit volume, making them a cost-effective solution for many applications. This cost-effectiveness, combined with their durability and longevity, provides a favorable return on investment. The material's lightweight nature also reduces transportation costs, further enhancing its economic appeal. The balance between cost and performance is a crucial consideration for industries seeking to optimize their operations and maximize profitability. The search for a reliable Pp Corrugated Sheet Manufacturer In India or a Pp Corrugated Sheet Manufacture Near Me often involves comparing prices and evaluating the quality of the material and the services offered.

Conclusion:

The rigid PP corrugated sheet represents a confluence of structural ingenuity, chemical resilience, and economic efficiency. Its unique fluted design, combined with polypropylene's inherent properties, makes it a versatile and reliable material for a wide range of industrial applications. From packaging and signage to construction and agriculture, PP corrugated sheets provide a robust and cost-effective solution that meets the demands of diverse industries. As industries continue to evolve and seek sustainable and efficient materials, the demand for rigid PP corrugated sheets is expected to grow. The accessibility of local manufacturers and the competitive pricing in markets like India further solidify its position as a preferred material in the industrial landscape.

FAQs:

What are the primary advantages of using rigid PP corrugated sheets compared to other materials?

Rigid PP corrugated sheets offer an exceptional strength-to-weight ratio, chemical resistance, impact resilience, and weatherability. They are also cost-effective and recyclable, making them a sustainable choice for various industrial applications.

How does the fluted structure of PP corrugated sheets contribute to their strength and durability?

The fluted structure acts as a series of miniature shock absorbers, distributing stress evenly across the sheet and preventing buckling or deformation. This design provides significant reinforcement without adding excessive weight, making the sheets strong and durable.

What are the common applications of rigid PP corrugated sheets in different industries?

They are used in packaging for protective containers, in signage for outdoor displays, in construction for temporary walls, and in agriculture for greenhouse panels and plant protectors. Their versatility makes them suitable for a wide range of industrial applications.

How does the cost of PP corrugated sheets compare to other materials, and what factors influence the price?

PP corrugated sheets are generally more cost-effective than traditional materials like wood or metal due to their lower cost per unit volume and lightweight nature. The Pp Corrugated Sheet Price In India is influenced by factors such as sheet thickness, customization, and the manufacturer's location and reputation.