The automotive heat shield market disruptions are reshaping how manufacturers design, produce, and deliver heat shielding solutions. While the market has grown steadily with increasing vehicle production and technological advancements, recent disruptions have introduced new challenges and opportunities. These disruptions stem from emerging technologies, supply chain complexities, evolving regulations, and changing consumer demands. Understanding these factors is essential for stakeholders to adapt and thrive in the transforming automotive landscape.

Technological Disruptions: Advanced Materials and Manufacturing

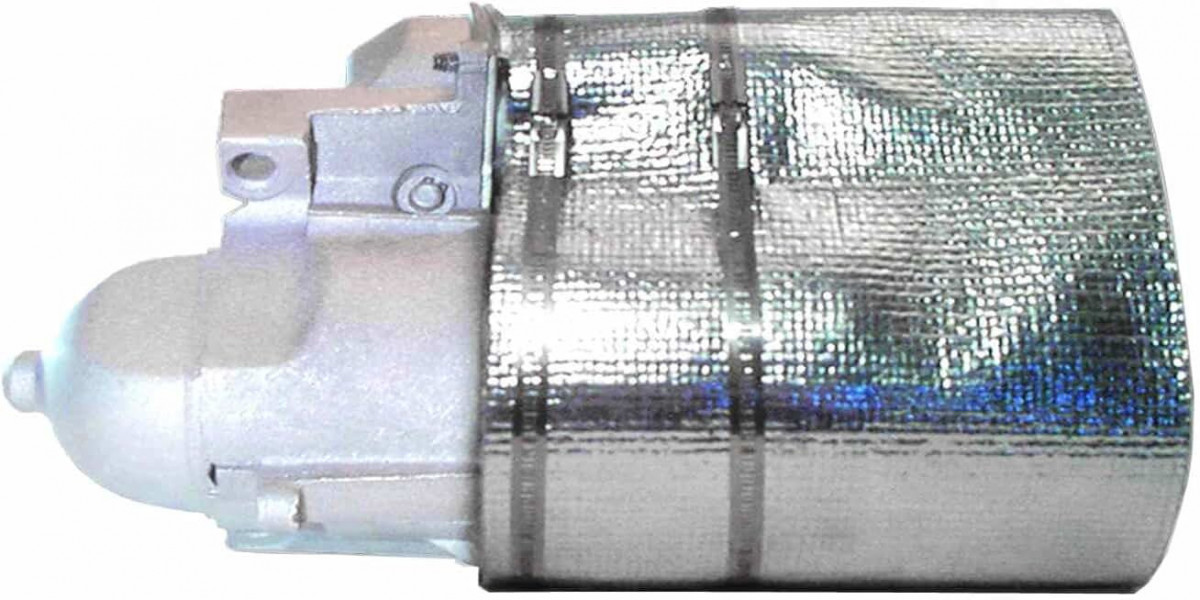

One of the most significant disruptions in the automotive heat shield market is the rapid evolution of materials and manufacturing technologies. Traditional metal-based heat shields are increasingly being replaced by lightweight composites, ceramics, and multi-layered materials that offer superior thermal performance and reduced weight.

Additive manufacturing (3D printing) and automated production processes are transforming heat shield fabrication, enabling complex designs and faster prototyping. While these advancements improve product capabilities, they also disrupt existing manufacturing setups, requiring significant investment in new equipment, skills, and R&D.

Shift Towards Electrification and New Vehicle Architectures

The global push toward electric vehicles (EVs) and hybrid models is fundamentally disrupting the automotive heat shield market. Unlike internal combustion engine (ICE) vehicles, EVs generate heat in batteries, inverters, and electric motors, necessitating entirely different thermal management solutions.

This shift forces heat shield manufacturers to innovate quickly and adapt their products to new heat profiles and installation requirements. Companies that cannot pivot effectively may lose market share, while those embracing EV-centric designs stand to gain from this disruption.

Supply Chain Volatility and Raw Material Scarcity

Recent global events, including pandemics and geopolitical tensions, have exposed vulnerabilities in automotive supply chains. The heat shield market, reliant on specialized raw materials like aluminum alloys, ceramics, and advanced composites, faces significant supply chain disruptions.

Material shortages, shipping delays, and rising costs directly impact production timelines and profitability. These challenges compel manufacturers to diversify suppliers, increase inventory buffers, and explore alternative materials to mitigate risk—a major disruption to traditional procurement strategies.

Regulatory Changes and Environmental Standards

Evolving regulatory frameworks present another layer of disruption. Governments worldwide are tightening emission controls, vehicle safety standards, and environmental compliance rules. Heat shields play a critical role in meeting these requirements by protecting components and reducing thermal emissions.

However, frequent changes in regulations demand agile product development and rapid certification processes. Compliance costs rise, and failure to adapt quickly can result in market exclusion, putting pressure on manufacturers to stay ahead in a dynamic regulatory environment.

Competitive Pressure from Emerging Thermal Management Technologies

The automotive heat shield market is also disrupted by alternative thermal management solutions. Technologies such as active cooling systems, thermal barrier coatings, and phase-change materials offer new ways to control heat.

Automakers may choose these alternatives over traditional heat shields based on efficiency, cost, or design flexibility. Heat shield manufacturers must innovate and integrate with complementary technologies to remain relevant and competitive.

Digital Transformation and Data-Driven Innovation

Digital technologies are disrupting product development and quality assurance in the automotive heat shield sector. The adoption of simulation software, IoT-enabled sensors, and artificial intelligence (AI) enhances thermal analysis, design optimization, and predictive maintenance.

While these tools improve efficiency and product reliability, they require substantial investment in digital infrastructure and skilled personnel. Companies that lag in digital adoption risk falling behind competitors who leverage data-driven innovation.

Changing Consumer Preferences and Market Demand

Consumer demand is shifting towards greener, safer, and more efficient vehicles, indirectly disrupting the heat shield market. Buyers increasingly expect vehicles with lower emissions, better fuel economy, and advanced safety features, influencing automaker design choices.

This trend pressures heat shield manufacturers to deliver solutions that contribute to lightweighting, sustainability, and enhanced performance. Failure to meet these expectations can reduce product attractiveness and limit market opportunities.

Impact of Geopolitical and Economic Instability

Geopolitical tensions and economic uncertainties, including trade wars and fluctuating tariffs, create disruptions affecting global automotive supply chains and investment decisions. Heat shield manufacturers operating internationally face challenges such as cost unpredictability, restricted market access, and shifting demand patterns.

Adapting to these economic disruptions involves strategic realignment, diversification of markets, and flexible production capabilities.

Industry Consolidation and Competitive Landscape Shifts

The heat shield market is witnessing consolidation as larger players acquire smaller firms to enhance technological capabilities and market reach. This consolidation disrupts traditional competitive dynamics by creating entities with more resources for innovation and global expansion.

While beneficial for scale and R&D, consolidation may reduce supplier diversity and bargaining power for automakers, reshaping market relationships and pricing structures.

Conclusion

The automotive heat shield market disruptions driven by technological innovation, electrification, supply chain volatility, regulatory shifts, and changing consumer demands are fundamentally transforming the industry. Companies that embrace these disruptions with agility, investment in new technologies, and strategic foresight will be best positioned to succeed.

Navigating these challenges requires a proactive approach to innovation, risk management, and collaboration, ensuring sustainable growth amid ongoing market transformation.