In today’s fast-paced industrial world, efficiency and precision are key. Traditional cleaning methods like sandblasting, chemical cleaning, or manual scrubbing are becoming outdated due to their environmental impact, high operational costs, and inefficiency. Enter laser cleaning machines—a revolutionary technology that offers a faster, safer, and more eco-friendly solution.

If you're considering upgrading your cleaning process, understanding the laser cleaning machine price and its long-term benefits is essential.

What is a Laser Cleaning Machine?

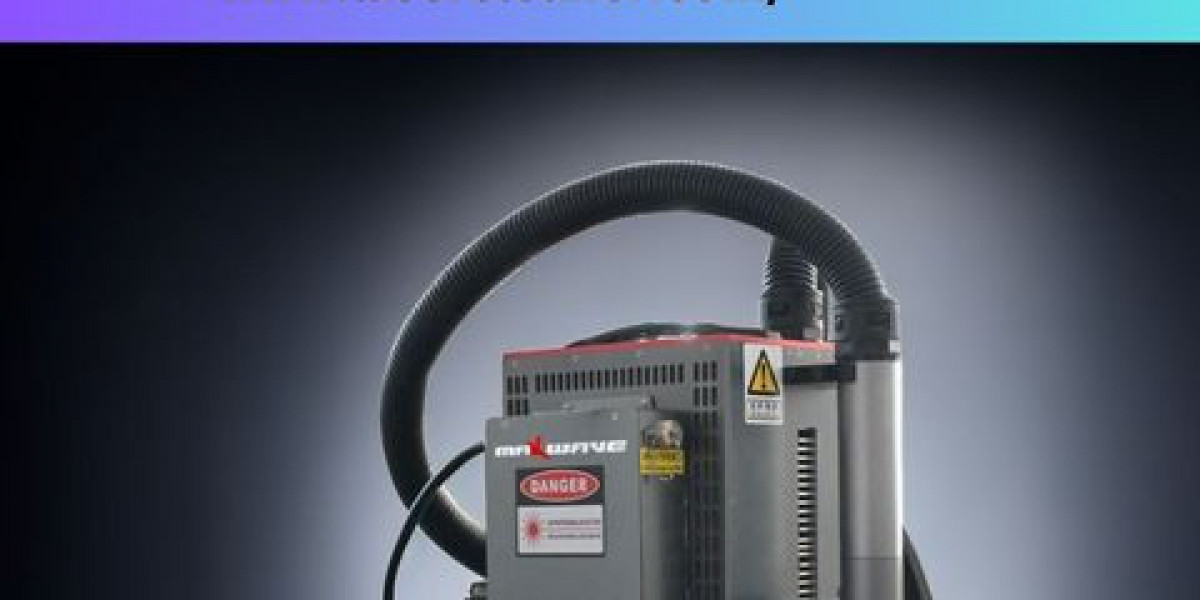

A laser cleaning machine uses high-intensity laser beams to remove rust, paint, oxides, and other contaminants from metal, plastic, and even delicate surfaces. Unlike abrasive methods, it doesn’t damage the underlying material, making it ideal for automotive, aerospace, heritage restoration, and manufacturing industries.

Why Choose Laser Cleaning Over Traditional Methods?

Eco-Friendly – No harmful chemicals or abrasive media means reduced waste and pollution.

Precision Cleaning – Targets only the unwanted layers without affecting the base material.

Cost-Effective – Lower long-term costs due to minimal consumables and maintenance.

Non-Contact Process – Eliminates wear and tear on tools and workpieces.

Versatility – Works on metals, ceramics, composites, and even sensitive historical artifacts.

Factors Affecting Laser Cleaning Machine Price

The laser cleaning machine price varies depending on several factors:

Laser Power – Higher wattage (50W to 1000W+) machines cost more but clean faster.

Automation Level – Handheld units are cheaper, while robotic or CNC-integrated systems are pricier.

Brand & Quality – Reputable manufacturers like LasersCleaner offer reliable machines with better after-sales support.

Additional Features – Cooling systems, safety enclosures, and software controls add to the cost.

Entry-level handheld models start around 5,000∗∗,whileindustrial−gradeautomatedsystemscanexceed∗∗50,000. However, the ROI is justified by reduced labor costs, minimal waste disposal fees, and increased productivity.

Is a Laser Cleaning Machine Worth the Investment?

Absolutely! While the upfront laser cleaning machine price may seem high, the long-term savings make it a smart choice. Businesses report:

50-70% faster cleaning compared to sandblasting.

No recurring costs for abrasives or chemicals.

Improved workplace safety with no toxic fumes or dust.

For industries dealing with rust, coating removal, or precision cleaning, investing in a high-quality laser cleaner from trusted suppliers like LasersCleaner ensures durability and performance.

Final Thoughts

Laser cleaning technology is transforming industrial maintenance, offering a cleaner, faster, and more sustainable alternative. By evaluating your needs and budget, you can find a machine that delivers the best value.

Ready to explore options? Check out the latest models and competitive pricing from industry leaders to make an informed decision.