The Enclosed Motor Starter Market is witnessing dynamic shifts as smart manufacturing practices and Industry 4.0 principles reshape global industrial landscapes. As factories modernize and digitize operations, demand for enclosed motor starters is evolving beyond traditional safety and control roles into intelligent components of interconnected production systems. This shift is prompting manufacturers to reimagine product designs, functionalities, and integration capabilities to meet next-generation industrial requirements.

Evolving Market Landscape

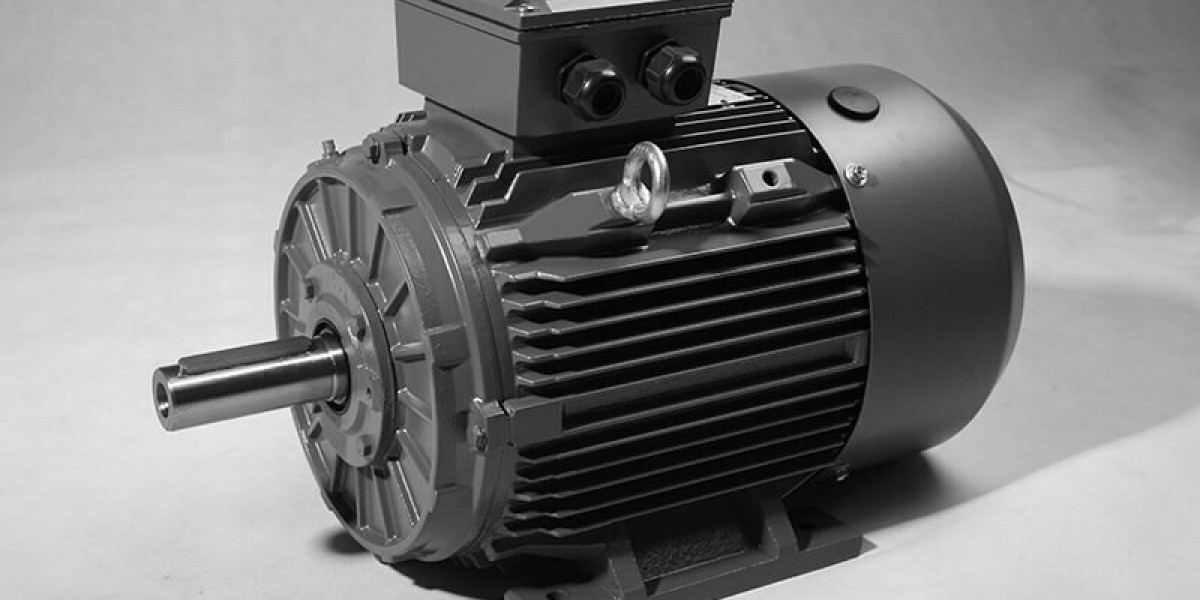

Traditionally, enclosed motor starters have played a foundational role in protecting and starting electric motors, especially in rugged industrial settings. However, as production lines become increasingly automated and data-driven, these devices must now perform more than mechanical switching—they must integrate seamlessly into smart ecosystems.

Smart manufacturing, characterized by the convergence of IoT, data analytics, AI, and cyber-physical systems, is influencing what end-users expect from their motor control equipment. The enclosed motor starter market is responding with innovations that align with the principles of efficiency, real-time control, and predictive intelligence.

Smart Manufacturing: Redefining Product Requirements

1. Real-Time Monitoring and Diagnostics

One of the clearest impacts of Industry 4.0 on the enclosed motor starter market is the demand for real-time data. Smart starters are now equipped with sensors and microcontrollers that allow them to monitor temperature, current, voltage, and other performance metrics continuously.

This live data enables predictive maintenance strategies, reducing unplanned downtime and increasing equipment longevity. It also aligns with the broader goal of maintaining uninterrupted production in smart factories.

2. Connectivity with Industrial Networks

Smart factories depend on connected systems, and enclosed motor starters must now support standard industrial communication protocols such as Modbus, PROFIBUS, and Ethernet/IP. These protocols allow seamless integration into supervisory control and data acquisition (SCADA) and distributed control systems (DCS), making starters active nodes in an intelligent network.

This networked capability facilitates centralized control, remote access, and data-driven decision-making—key features of any modern manufacturing facility.

3. Compact and Modular Design

Space efficiency is another priority in smart manufacturing environments, especially as equipment density increases. In response, manufacturers are developing enclosed motor starters with modular, space-saving designs that support quick installation, easy customization, and minimal wiring.

These modular systems not only save valuable panel space but also simplify maintenance and scalability, allowing facilities to expand or modify production lines with minimal downtime.

Industry 4.0 Impact Across Key Sectors

1. Automotive and Electronics

High levels of automation in automotive and electronics manufacturing are creating strong demand for intelligent motor control systems. Enclosed motor starters with advanced fault detection and diagnostic features are particularly valued in these sectors, where production continuity and precision are paramount.

2. Food and Beverage Processing

This sector benefits from enclosed starters that combine smart capabilities with high ingress protection. Hygienic designs, resistance to washdowns, and built-in communication interfaces allow these starters to operate effectively in both automated and sanitary environments.

3. Energy and Utilities

In power generation, water treatment, and other utility services, Industry 4.0 is driving the adoption of predictive maintenance. Enclosed motor starters with data logging, condition monitoring, and cloud connectivity are helping facilities manage assets more efficiently and reduce operational risks.

Challenges to Adoption

While smart manufacturing is driving growth, the transition is not without challenges:

High Initial Investment: Advanced enclosed motor starters with digital features often come at a premium, which may limit adoption among small and mid-sized enterprises.

Technical Skills Gap: Implementing and managing smart starters requires skilled personnel familiar with industrial networking and automation protocols.

Legacy System Integration: Many industrial facilities still operate with legacy equipment, and integrating smart starters can require significant upgrades or complex retrofitting.

Regional Trends and Market Shifts

North America and Europe

These mature markets are at the forefront of Industry 4.0 adoption, with governments and industry bodies supporting the transition through grants and innovation hubs. Demand for smart starters is strongest in manufacturing-intensive regions, particularly in Germany, the U.S., and the U.K.

Asia-Pacific

Rapid industrialization, combined with governmental pushes for automation in countries like China, India, and South Korea, is creating strong demand for modern enclosed motor control systems. Smart city initiatives and new industrial corridors are accelerating adoption.

Latin America and Middle East

While slower in adopting full-scale Industry 4.0, these regions are beginning to explore smart manufacturing, particularly in oil & gas and mining. Enclosed motor starters that provide remote diagnostics and rugged durability are gaining popularity.

Future Outlook: Smart and Sustainable

As Industry 4.0 becomes the new standard in global manufacturing, enclosed motor starters will increasingly be evaluated based on their ability to contribute to smart, safe, and sustainable operations. Environmental sustainability is also becoming a consideration, prompting manufacturers to use recyclable materials and energy-efficient designs.

The future of the market lies in convergence—merging digital intelligence with traditional robustness to support next-generation manufacturing.

Conclusion

Smart manufacturing and Industry 4.0 are transforming the enclosed motor starter market, pushing manufacturers to innovate and redefine product functionalities. Real-time monitoring, network integration, and compact designs are emerging as key differentiators. With these advancements, enclosed motor starters are no longer passive devices but active contributors to intelligent, efficient, and data-driven production ecosystems.